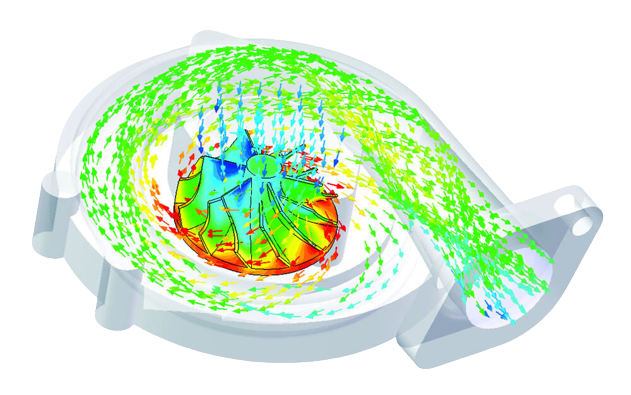

Our simulation and testing services can help identify potential issues before they occur, reducing the risk of costly and time-consuming redesigns

We also provide detailed test reports and analysis, allowing our clients to make informed decisions about their products. Contact us today to discuss your project and find out how we can help ensure the performance and reliability of your product.

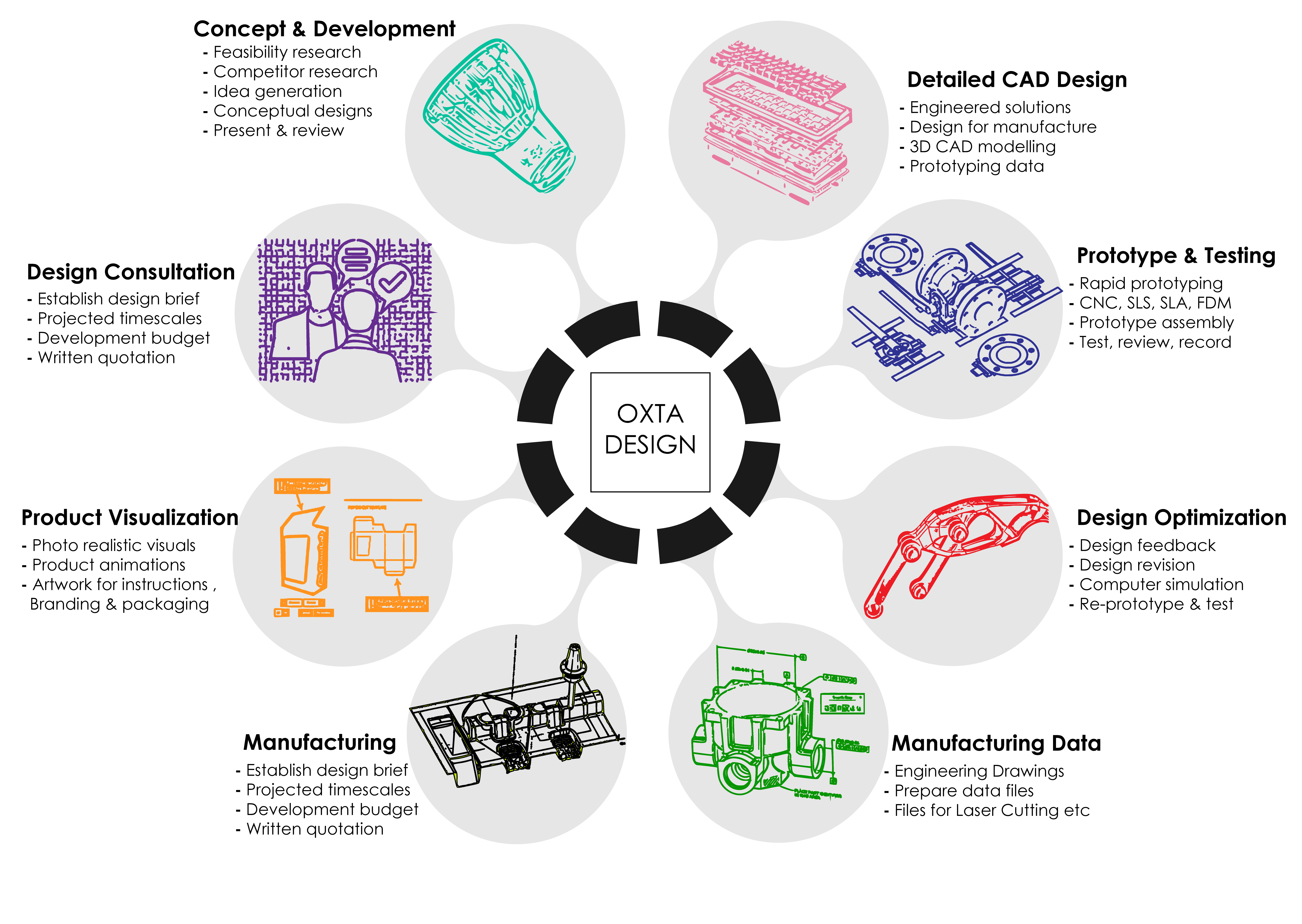

Mechanical simulation and testing services are an integral part of the product development process, ensuring that a product performs as intended and meets safety and regulatory requirements. These services may include the following:

-

Finite element analysis (FEA): This is a computerized method for predicting how a product reacts to real-world forces, vibration, heat, fluid flow, and other physical effects. This analysis can be used to improve the product’s strength, durability, and overall performance.

-

Computational fluid dynamics (CFD): This is a simulation technique for analyzing the behavior of fluids and gases. It can be used to optimize the performance of systems such as HVAC, heat exchangers, and combustion engines.

-

Dynamics and vibration analysis: This is the study of how a product behaves when it is subjected to dynamic loads, such as vibration or shock. This analysis can be used to identify potential problems and improve the product’s durability.

-

Testing and validation: This involves physically testing the product to verify that it performs as intended and meets relevant standards and regulations. This can include testing for strength, durability, safety, and compliance with industry standards.

Collaborative Approach

Creative Ideas

Projects

At Oxta Design, we don’t just work for you; we work with you. We integrate with your team, forming close working ties that foster creative synergy and mutual growth. Our personal approach sets us apart, and it’s why our clients trust us to design products that distinguish their brands from the competition

Our Expertise include

Our mechanical simulation and testing services team is made up of experienced engineers and technicians who are well-versed in industry-standard simulation and analysis software and testing techniques. We use state-of-the-art equipment and facilities to provide our clients with accurate and reliable results.

We work with clients in a wide range of industries, including:

-

Automotive: We have experience simulating and testing mechanical systems and components for cars, trucks, and other vehicles.

-

Aerospace and defense: We have experience simulating and testing mechanical systems and components for aircraft, missiles, and other defense-related applications.

-

Industrial machinery: We have experience simulating and testing mechanical systems and components for industrial equipment, such as pumps, compressors, and conveyors.

-

Medical devices: We have experience simulating and testing mechanical systems and components for medical equipment and devices.

Why Us

It is crucial to consider an idea's commercial viability because a concept is only as good as its intent and application. The prototype is finally prepared for mass production once it has been determined to be viable and marketable.

We have created a variety of products at Oxta Design. Our team has years of experience creating unique items that consumers want to buy. These consist of both textile and non-textile items.

We'll produce something that is profitably sound, visually appealing, attractive, and functional by combining your vision with our knowledge of concept creation and product design.